Flanged Immersion Heaters: A Comprehensive Guide for Industrial Applications

Industrial processes require efficient heating systems for a variety of purposes. They maintain temperatures in pipelines and tanks, heat liquids and gasses, keep product quality intact, and provide quick and reliable heating solutions.

Flanged immersion heaters are versatile and one of the best choices when looking for heating systems, especially for industrial usage. Whether you’re considering upgrading your heating systems or simply exploring your options, understanding the benefits and applications of flanged immersion heaters is essential.

5 Reasons Why You Should Opt for Flanged Immersion Heaters

Flanged immersion heaters are highly efficient and come in diverse uses. From heating liquids and gasses to help maintain temperatures in pipelines, there are numerous reasons why you should choose flanged immersion heaters.

1) What Are Flanged Heaters?

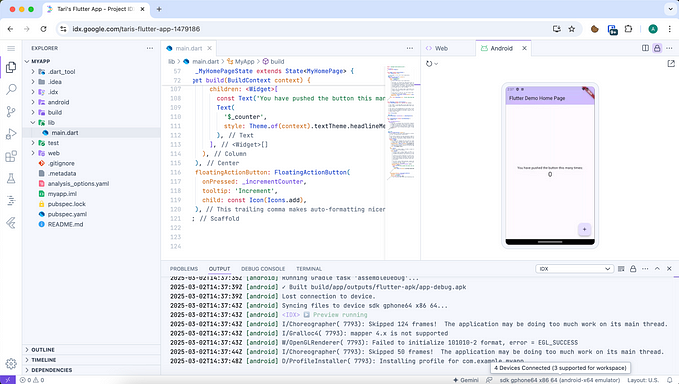

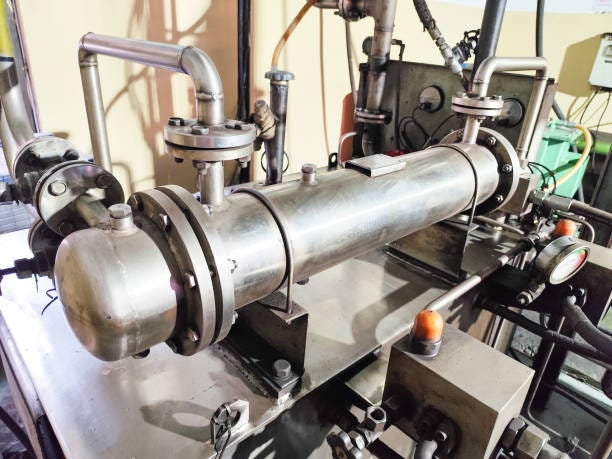

Flange heaters are electric elements mounted on pipelines or flanges that help with easy installation and connection between pipelines, tanks, and reservoirs. These heaters submerge directly into what needs heating, be it a liquid, an oil, or any other chemical solution.

The flange secures the heater to the tank or vessel, ensuring a leak-proof fit. The design of flanged immersion heaters reduces energy loss and provides quick heating by facilitating effective heat transmission directly to the substance.

They are perfect for tricky industrial settings where reliability and durability are crucial because of their sturdy design and adaptable setups.

2) Versatile Applications in Industrial Heating Systems

Industrial systems are diverse when it comes to different uses and applications. Flanged immersion heaters are used for chemical processing and maintaining corrosive fluid temperatures across pipelines.

Not only that, flanged immersion heaters also help in food processing industries where maintenance of a constant temperature requires heating, like in pasteurization and sterilization.

They also help heat oils and gasses like petroleum or crude oil, water treatment in large-scale tanks, and power plants for heating lubricants, hydraulic oils, and other fluids critical to machinery operation.

3) Efficiency and Design

Flanged immersion heaters provide high efficiency because they come with direct submersion, which allows for better heating and relatively less energy consumption.

They also come with a compact and minimal design, taking up less space in comparison to other industrial heating solutions, making them ideal for facilities with limited room. They are also durable and consist of non-corrosive materials like different alloys or stainless steel.

They also come with easy maintenance; the flange design makes installation and removal simple, reducing downtime during repairs or replacements.

4) Safety Features and Application-Specific Needs

When talking about safety, it is primary to consider the flanges’ material and make sure that they are non-corrosive and do not react with any particular fluid or chemical in use.

Safety mechanisms like thermocouples or over-temperature protection can prevent damage to the heater and surrounding equipment. Other than that, what also needs your attention is the watt density. Choose an appropriate watt density that matches the material’s thermal conductivity.

Consider whether additional features, such as explosion-proof designs or extended elements, are necessary for your specific needs.

5) Maintenance and Longevity of Flanged Immersion Heaters

Proper maintenance is essential for flanged immersion heaters to operate as efficiently and as long as possible. Do the inspection checks on a regular basis.

Verify the electrical connections and flange are tight and undamaged. Also, it is critical to remember to routinely inspect thermocouples, temperature sensors, and over-temperature devices to ensure appropriate operation.

To prevent leaks or inefficiencies, replace worn-out components or seals as soon as possible.

Conclusion

These heaters are great at providing reliable, energy-efficient heating solutions for everything from chemical processing to water treatment.

To ensure an ideal fit for your application, consider factors like watt density, safety features, and material compatibility when selecting a flanged immersion heater. These heaters are excellent for industrial businesses since they may provide years of dependable service with the right upkeep.

Flanged immersion heaters are a tried-and-true option for industrial settings if you want to install new heating systems or improve existing ones.

Speak with professionals in industrial heating systems to investigate customized solutions that will satisfy your requirements and maintain the efficiency of your business.