Comparing Flange Dimensions Across Different Standards: A Quick Guide

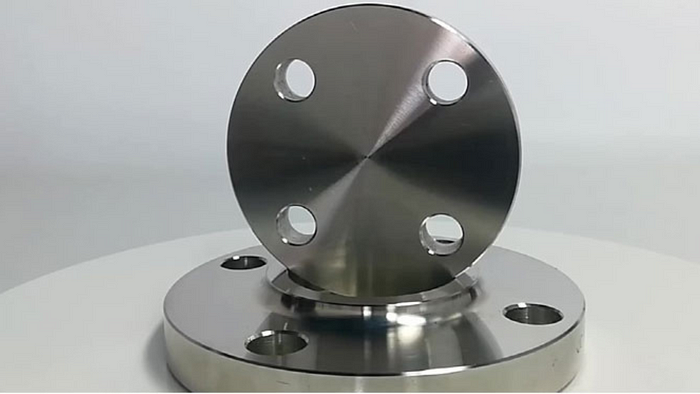

In any given industrial project, the selection of flange is extremely crucial. Flanges help in joining pipes, valves, pumps, and other structures. Yet, not all flanges are the same.

These flange dimensions are characterized by half of the bolt circle, though various standards exist and may differ greatly. It is important to understand these differences if you want your project to be compatible and safe.

This guide will help you know about the fundamental features of flanges and their comparison based on different standards.

Why Flange Dimensions Matter?

It is important how flange dimensions play a significant part in the right performance and safety of your piping system. If the size of the flanges does not match those of the pipes or equipment, it can lead to leakages, system failure, or even disastrous outcomes.

These are the outer diameter, thickness, bolt circle diameter, and the number of bolt holes, among others. This means that all these dimensions have to be right in order to get the proper fit.

Common Flange Standards

The following are some of the standards that regulate the dimensions of flanges. The most popular standards are ANSI/ASME, DIN, and JIS standards. Every standard has its given specifications, and by knowing those, one can choose the suitable flange.

1. ANSI/ASME B16.5

- This standard is common in most North American countries. It defines dimensions of flanges for diverse pressures, among them #150, #300, #600, and others.

- Flanges made to this standard are typically present in inches.

- ANSI/ASME flanges are strong flanges and are common under high-pressure conditions.

2. DIN

- The DIN standard is common in many European countries. DIN flanges are in millimeters, unlike ANSI/ASME flanges.

- This standard involves different pressure classes labeled by the abbreviation PN for Pressure Nominal, like PN10, PN16, PN25, and so on.

- DIN flanges are used mainly in sectors such as petrochemicals, mechanical engineering, and construction.

3. JIS

- The abbreviated term for Japanese Industrial Standards is JIS. These flanges are common in Japan and most of the Asian countries.

- Like DIN flanges, the measurement of JIS flanges is also in millimeters as well. They also have different pressure ratings, including 5K, 10K, 20K, and more.

- Relatively, JIS flanges are common in areas of professional engineering, such as the automotive and manufacturing industries.

Comparing Flange Dimensions

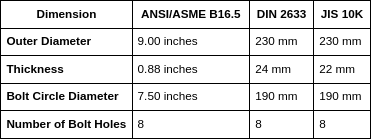

For a better understanding of these standards, let us consider the dimensions of a 4-inch, 150# flange as per ANSI/ASME, DIN, and JIS standards.

From this comparison, you can see that while some dimensions are similar, others can vary. For instance, the thickness of the JIS flange is lower than the thickness of the ANSI/ASME and DIN flanges. Even minor variations in the size of the flange can affect its efficiency in some specific fields.

Key Considerations When Selecting a Flange

When choosing a flange, it’s important to consider the following factors:

- Application

It is also important to consider the nature of the fluid, gas, or material that will flow through the system. In some situations, such as in high-pressure and temperature environments, there may be a need to use certain flange standards such as the ANSI/ASME.

- Region

Another factor that you might consider is the location of your project or study. There are two types of flange standards in North America, namely ANSI/ASME flanges, and the other standard used in Europe is DIN flanges. For projects located in Asia, JIS flanges may be easier to obtain.

- Compatibility

Check that the flange will fit both the pipe and the equipment in terms of diameter and material type. There are potential compatibility problems when using more than one standard in a single system.

- Cost

It is also quite flexible depending on the flange standard and type of material used. Sometimes, it might be more reasonable to use one standard over another depending on, for instance, the equipment already in place for the said standard.

- Availability

Market research: Find out whether the flange you are thinking of purchasing is available in the market. Some flange standards may be hard to find, and this will slow down your project.

Conclusion

It is crucial to note that the dimensions of flanges are very relevant to the outcome of any industrial undertaking. It is important to note how these dimensions may differ from the standard, such as ANSI flange dimensions/ASME, DIN, or JIS, in order to achieve appropriate compatibility and safety standards.

So, by making critical decisions on application, region, compatibility, cost, and availability, it is possible to make the right choice in flange standards.